Screw conveyors are a great way to streamline the manufacturing process or transport bulky materials from one location to another to speed up your applications. They find purpose in various industries, such as construction, chemicals, food, grain, wastewater, recycling and many more.

A Screw conveyor is often a more feature-rich and affordable alternative to belt conveyors. It’s a cost-saving investment that ensures you avoid tedious manual labour. It also automates a larger part of your process whilst your staff ensures the quality of your applications.

But how do you know which screw conveyor is suitable for your purposes? Here are 8 tips to get you started.

1. Know Your Product

The first step to choosing a suitable screw conveyor is to know precisely what you will be conveying. This is important to specify certain features and materials the screw conveyor needs.

Is your product:

- Free-flowing, like liquids or powders? Or is it non-flowing, like heavy rubble?

- Non-uniform? Irregularly shaped pieces could risk clogging up the conveyor if not designed with the correct specifications.

- Abrasive? This will affect which material your housing needs to be made out of.

- Sticky? Screws can get clogged with product build-up. The suitable screw conveyor will have a design that avoids this issue.

- Sensitive to contamination or prone to absorbing moisture?

2. Consider How Your Product Needs to Move

Next, you’ll need to figure out how the product will be moved on site. This determines what type of screw conveyor is suitable for you.

Horizontal screw conveyors move the product along a simple horizontal line.

Inclined screw conveyors move product at an incline of up to 45 degrees. The higher the pitch, the least efficient they are, so keep this in mind when you decide on the space your conveyor will be set up in!

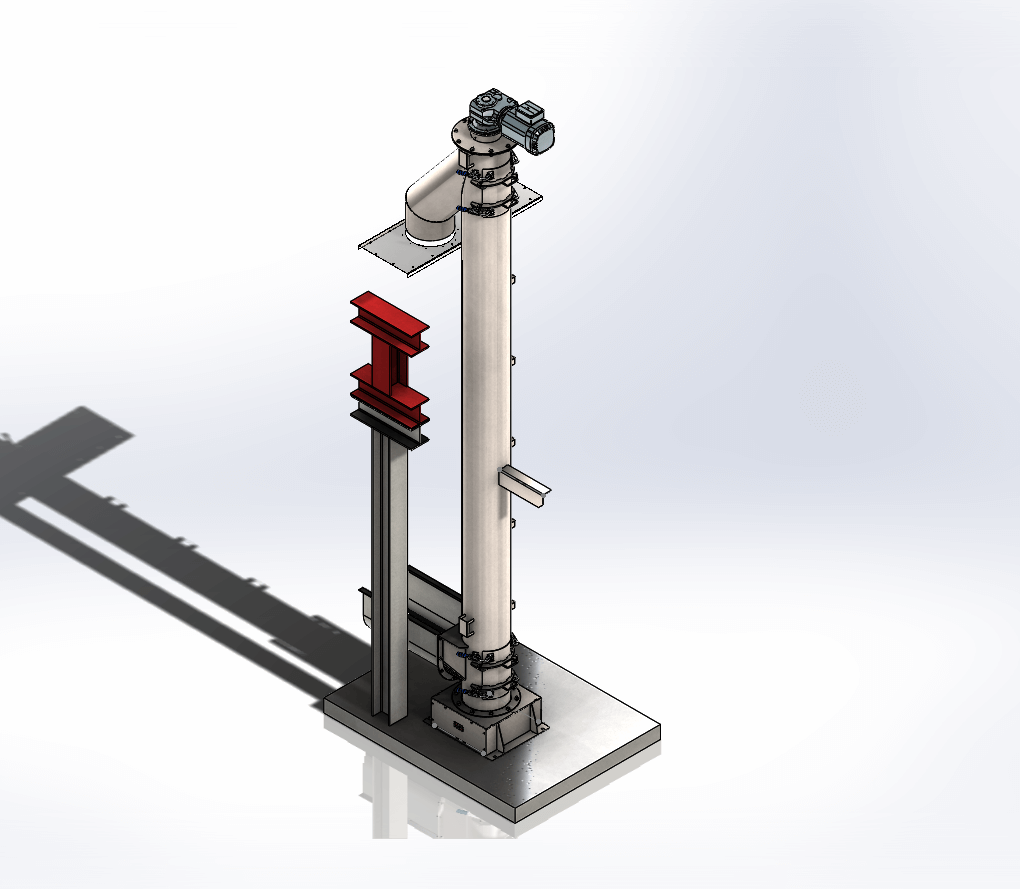

Vertical screw conveyors move products on a vertical axis, for example, up or down to another floor. Vertical screw conveyors are often paired with feeders that can dispense the same quantity of product at specified intervals.

You should also consider what speed your product needs to move and what volume your screw conveyor will handle. This will determine how much power your chosen screw conveyor has to provide.

3. Find the Right Screw Type for Your Product

Once you know your product, you can more easily determine how the screw in your conveyor should be designed.

Free-flowing materials require screws with a larger diameter and a short pitch.

Sticky or viscous product benefits from shaftless screws that let the product flow through freely.

Products with irregular particle sizes can interlock and might benefit from screws with an oversized pipe and thicker flights that better control how much product is conveyed at any given time.

4. Choose the Right Material

Some product is hazardous and has unique material requirements. This affects the coating of the screw conveyor’s screw, housing and other parts. For example, the abrasive product requires non-abrasive materials like hard-surfaced steel.

Suppose there is a risk of your product sparking and causing an explosion. In that case, your screw conveyor should be constructed from different metals to reduce the likelihood of sparks under friction.

5. Seal or no Seal?

Toxic products or products easily contaminated by moisture or air might need air-tight housing and seals at the end of the shaft. In addition, ensure that your conveyor comes with a dust-tight shaft seal and other seals to prevent contamination from seeping in or toxic fumes from escaping. This ensures both the safety of your product and your employees.

Consider Special Requirements

Consider if there are other special requirements your screw conveyor has to meet, such as the ability to:

- Dispense product at multiple locations

- Start and stop with a sensor that measures product flow

- Flow at a variety of speeds

Heat or cool product whilst in the conveyor

7. Think of The Accessories

A full set-up might require more than just a screw conveyor. In many cases, you may want to pair your new device with bins that can catch product, sampling systems, or feeders that control the product flow. Ensure that you know how the whole process will work when choosing your screw conveyor.

8. Let the Experts Help with the Specifications

Choosing a screw conveyor is no easy task, but luckily you don’t have to do it alone!

The Wrights Dowson Group is the most trusted manufacturer of screw conveyors in the UK. With decades of experience under our belt, we know how to make the best screw conveyors for any application.

Our engineers are available to help you understand your requirements and create detailed specifications for the screw conveyor of your dreams. We consider your product, space, production process and objectives when we help you decide on the details of your screw conveyor.

Get in touch today to receive a quote or help with technical questions.