The Wrights Dowson Group is one of the leading Bin Discharger manufacturers in the UK. Their bin dischargers have been successfully used across several industries, including food, drink, animal feed and grain, waste, biomass and recycling and many others.

The discharge of powder, flakes, grains, pellets, or granules stored in bulk can be a challenge. Controlling such materials’ discharge can be a problem in industries such as food processing and chemical plants. Irrespective of whether the materials come from a silo or a bulk handling system, our clients understand the importance of controlling the rates at which those materials flow.

One such way to address this is by using a bin discharger.

What’s a Bin Discharger?

A bin discharger is used to discharge powder, flakes, grains, pellets and granular materials from storage bins. The Wrights Dowson Group bin dischargers are a proven and effective method in achieving this. They are used in conjunction with hoppers and silos. A bin discharger is an ideal piece of equipment to use when powder and granular materials are challenging to handle or transport because their characteristics make them hard to control or release.

A bin discharger can control the discharge of the materials at either a fixed or variable flow rate. A bin discharger is also sometimes referred to as a Screw Bin Discharger.

Types of Materials Handled by a Bin Discharger

There are several typical materials handled by a bin discharger in the industries already referred to. These include:

- Flour

- Cement

- Coal

- Sawdust

- Spent Hops

- Sugar

- Gypsum

- Wood Flour

- Spent Grains

What’s the Design of a Bin Discharger?

The Wrights Dowson Group has an established history of designing bin dischargers for a variety of industries.

The design of a bin discharger varies according to our client’s specifications. However, there are several standard aspects to each, and these are listed below:

- A size range of between 160mm to 400mm in diameter. Specials up to 1000mm Diameter have been manufactured and commissioned successfully.

- A regular or heavy-duty construction

- Manufactured from either mild steel or stainless steel

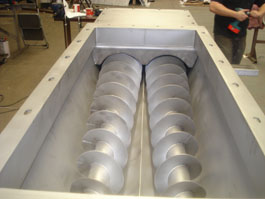

- A single or twin worm configuration

- A throughput capacity ranging from 2.8M3 per hour to 626 M3 per hour

Our bin dischargers also have an optional fixed or variable speed drive. The screw assemblies are either driven individually or by a common drive using spur gears.

The Wrights Dowson Group can also design a multi-worm bin discharger machine. These are ideal for wide inlet openings. Such bin dischargers, combined with tapered screws and troughs and special inlets and tailored casing lengths, can be designed to suit our clients’ specific requirements.

Advantages of Using a Bin Discharger

There are several significant advantages to using a bin charger alongside other mechanisms designed by the Wrights Dowson Group:

- Bin Dischargers have a compact but heavy-duty design and occupy minimal space.

- They manage the release of non-free-flowing materials and materials that are subject to fluidisation.

- Their simple design is a cost-effective solution to manage discharge problems.

- They have a safe design, and all their moving parts are enclosed, which ensures they are protected from dirt or dust.

- They operate at a slow speed with a quiet operation

- They are easy to maintain

- They do not vibrate

- They are not expensive to install

The Right Bin Discharger for Your Business

Our Wrights Dowson Engineers can advise you on what type of bin discharger can best suit your needs. Ideally, you will be able to provide us with the following information:

- Details of the bin outlet to which your discharger will be fitted

- The overall length of the discharger or the overall size, including the extended conveyor

- The maximum material discharge rate

- Details of the material that will be handled: in particular, the particle sizes and density. It would also help to know what condition the material is in – if it’s free-flowing, moisture content, etc.

Learn More

The Wrights Dowson Group has an established reputation for its design of bin dischargers and another bespoke engineering to suit our clients’ applications. We also design bespoke conveyors, rotary shaft seals, bin activators and more to suit your industrial operations.

If you want to find out more about our bin dischargers, get in touch with us at the Wrights Dowson Group for advice, technical support and a quotation.