For industrial and manual work, screw conveyors are a necessity. If you need to move and distribute bulk materials like cement, screw conveyors are a practical solution that can save effort, time, and money.

How Do Vertical Screw Conveyors Work?

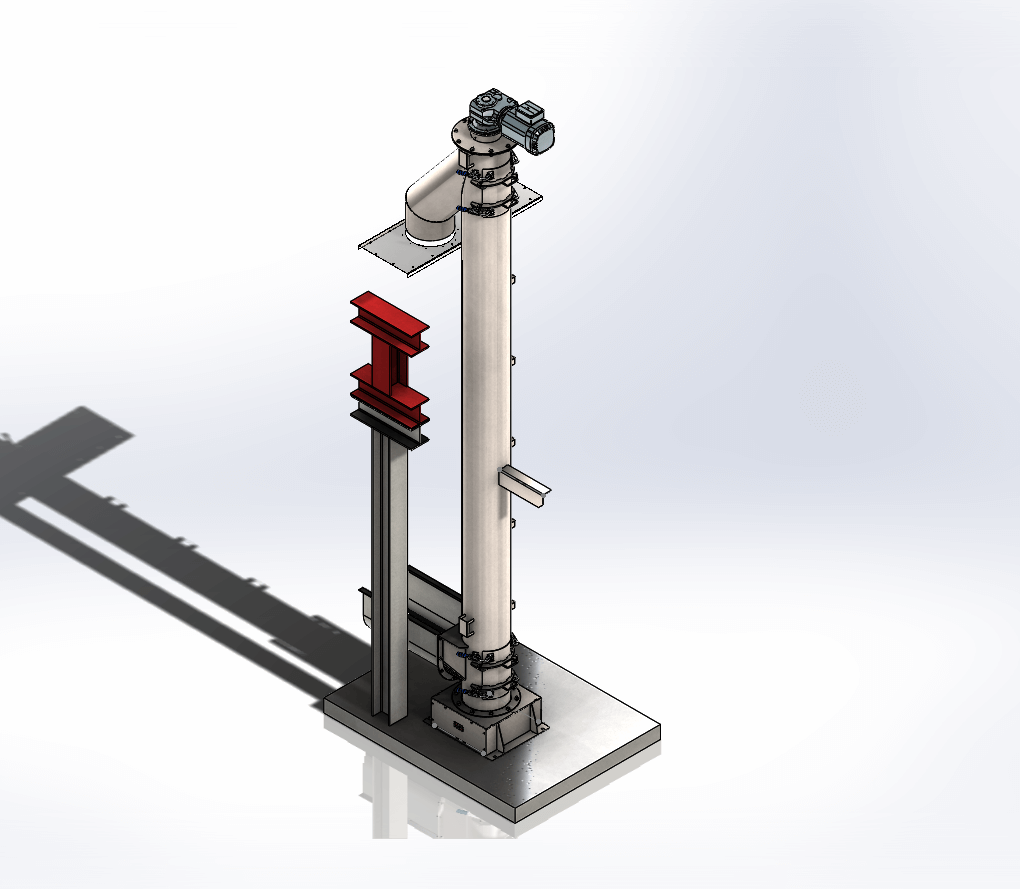

Vertical screw conveyors are positioned in an upright, and sometimes even wholly vertical, position. These conveyors can elevate heavy or bulk materials at steep inclines, and they’re used across a wide variety of markets. Vertical screw conveyors are also efficient space-savers; the maximum height of a screw conveyor can vary as it’s dependent on the volume of material it needs to convey. However, most vertical screw conveyors rarely exceed a height of around 50 feet.

The size and speed of a conveyor are dependent on the maximum volume being transported. Therefore, to avoid any damage to the machinery, it’s usually recommended that users first establish their maximum poundage (per unit of time). Then, to determine the volumetric capacity of the conveyor, divide the maximum poundage rate by the minimal level of density expected from the material.

Because of their design, vertical screw conveyors don’t come without their limitations. They’re not suited to convey all materials, and typically, dewatered sludge works or dried biosolids are conveyed best through their structure. Vertical conveyors act like compactors that release free water from the products that pass through them, filtering them to accumulate in a separate area like a trough. This makes them unsuitable for materials like grit, even when dewatered, as it can clog drains and damage the machinery.

How Does The Vertical Screw Convey Cement?

Moving cement is no small feat. For those working with cement regularly, vertical

screw conveyors are usually deployed to make the job easier. These conveyors are particularly useful for workers who need to load, unload and convey cement between ships and storage facilities. For these operations, workers typically use a combination of both horizontal and vertical screw conveyors.

With a horizontal crew conveyor, cement can be loaded into the ship’s holds longitudinally and crosswise. Then, the vertical screw conveyor will be used to keep the cement elevated above the deck level of the ship. One of the most significant benefits of using a screw conveyor is it offers a much lower power consumption than other types of equipment. Because they require less power, they can save energy and cut emissions whilst still getting the job done.

Vertical conveyors are also used in other areas of the cement industry, like to transport cement to silos and hoppers. In these instances, a horizontal screw feeder is installed below a silo or a hopper, and the conveyor feeds the material into it. The horizontal screw feeder then conveys this to the vertical screw conveyor used to elevate/load the powder to the required height needed to fill the hopper and/or silos. These conveyors are also popular in areas of rural India where facilities are not equipped to handle Pneumatic loading and/or bucket elevators.

When cement is packaged in bags, it often weighs more than it does when it’s being transported through the conveyor. This is because the weight of the cement changes when it passes through the conveyor as it begins to aerate, and the density diminishes. In some cases, this density can reduce by as much as 30-40lbs. This is why organisations seeking to use conveyors must do the appropriate calculations to avoid damaging their machinery.

To avoid complications, the stream of cement must also pass through the conveyor at a constant speed to prevent surge loads.

The Benefits of Using a Vertical Screw Conveyor

- Low maintenance

- Small environmental footprint

- Small dimensions – this makes them great for saving space and means they require fewer spare parts. This makes them a cost-effective alternative to other forms of machinery, too.

Each vertical screw conveyor is custom made to suit the job you require. This is what makes them so popular across an array of different industries. If you feel your business or organisation could benefit from a vertical screw conveyor, contact the Wrights Dowson Group today for more information.