For mineral companies, particularly those working with limestone products, a build-up of magnesium waste can occur regularly, and it can be challenging to transport. In large quantities, magnesium waste can be cumbersome, and it comes with risks to human life, making its safe transportation and disposal a closely regulated field.

Laws surrounding magnesium disposal can vary from country to country. However, most areas have their own state, local, or federal laws to determine the safest ways to dispose of magnesium waste. In certain conditions, magnesium waste can become combustible, and when burning, it reacts violently with water and moisture.

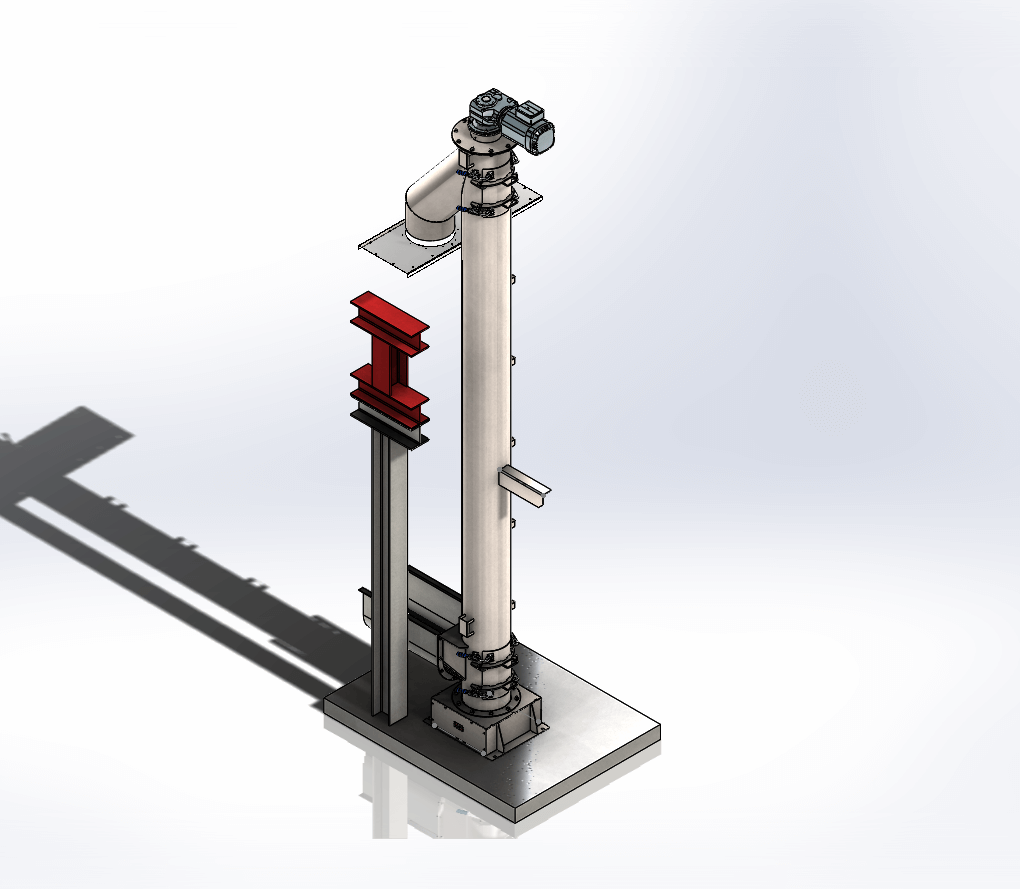

For companies wanting to recycle and incinerate magnesium waste efficiently, finding the right solution can be tricky. Incinerators are often large, tall structures, and waste needs to be lifted at height to enter them. This can be challenging for larger companies with large-scale incinerators that require even taller and efficient solutions to transport heavy loads of waste.

When incinerators are positioned at high, vertical angles, magnesium waste, which is notoriously difficult to transport anyway, can be tough to recycle. SMA Mineral Magnesia AS experienced this problem when they weren’t able to find the right equipment to lift their magnesium waste high enough to reach the incinerator. By chance, they discovered that a shaftless screw conveyor system that could raise their waste vertically was the answer.

Screw conveyors are designed to move liquid or granular materials in large quantities, making them a popular choice amongst bulk handling industries. Screw conveyors push material as the screw rotates in a fixed trough, pipe or housing. The shaftless screw conveyor is a relatively new development in the industry, and it has grown in popularity thanks to its many bulk solid handling applications.

In construction, the shaftless screw conveyor is very similar to the design of a shafted screw conveyor. The main difference between the two is in the spiral or screw of the conveyor. There’s a centre pipe in a shafted screw conveyor to support the screw flights, and the pipe is held in place by bearings. There’s usually a gap of around half an inch between the outside diameter of the screw and the inside of the trough. However, a shaftless conveyor is supported by a liner that fits the radius of the trough. The weight of the screw is spread across the entire length of the spiral on the liner. With a flanged and bolted drive shaft and a spiral endplate, the drive is attached to one end of the spiral, and the bottom-end is left to rotate freely. With this design, everything from catalysts to dewatered biosolids can be conveyed with ease.

When running tests on their vertical screw conveyor, SMA mineral magnesia AS discovered that “humidification has a positive effect on the running properties, this made magnesium less sticky. Also, by choosing a shaftless screw, bridging was considerably reduced, and vertical transport did become possible”.

Vertical screw conveyors can rise to an average height of 5m. Although many incinerators can reach heights of 14m and above, waste inputs are usually not situated at the peak. This makes the most robust vertical screw conveyors capable of reaching the appropriate heights needed to dispose of excess waste. For vertical screw conveyors to transport magnesium waste effectively, humidifiers nozzles will need to be fitted at various points in the installation process to ensure the hydrated magnesium is humidified as soon as the running properties are expelled.

The Wrights Dowson Group is one of the industry’s leading manufacturers of vertical screw conveyor. The group have experience working with the minerals, food ingredients and fresh food sector to provide optimal conveyor solutions that can maximise space without sacrificing throughput. These solutions can be manufactured as either a stand-alone system, an integrated plant system or in conjunction with a range of solids handling equipment. With high-quality materials and diameters of up to 300mm, these vertical screw conveyors provide a perfect solution for mineral companies looking to follow in the footsteps of SMA Mineral Magnesia AS and implement an effective, robust solution to transporting magnesium waste vertically.