The Wrights Downson group builds upon its reputation as one of the leading vertical screw conveyor manufacturers in the UK. Our screw conveyors have been successfully used across various industries, including food, drink, animal feed and grain, waste, biomass and recycling, and many more.

When transporting a product from one processing stage to another, no spillages must occur, and the product isn’t lost. This is vital for a clean and healthy work environment and protects the bottom line of your plant. Screw conveyors are widely used to transport material directly from one processing location to another within your plant, requiring less manual labour and bridging areas that are difficult to move across.

This is especially true for vertical screw conveyors that can move product from one floor to another. Our clients understand the importance of safely moving product with bulk handling equipment that can control the rate of discharge and keep materials safely contained.

Vertical screw conveyors fulfil these criteria.

What is a Vertical Screw Conveyor?

Vertical Screw Conveyors come with all the benefits of ordinary screw conveyors. However, they have the added advantage of moving product at a steeper angle or even vertically.

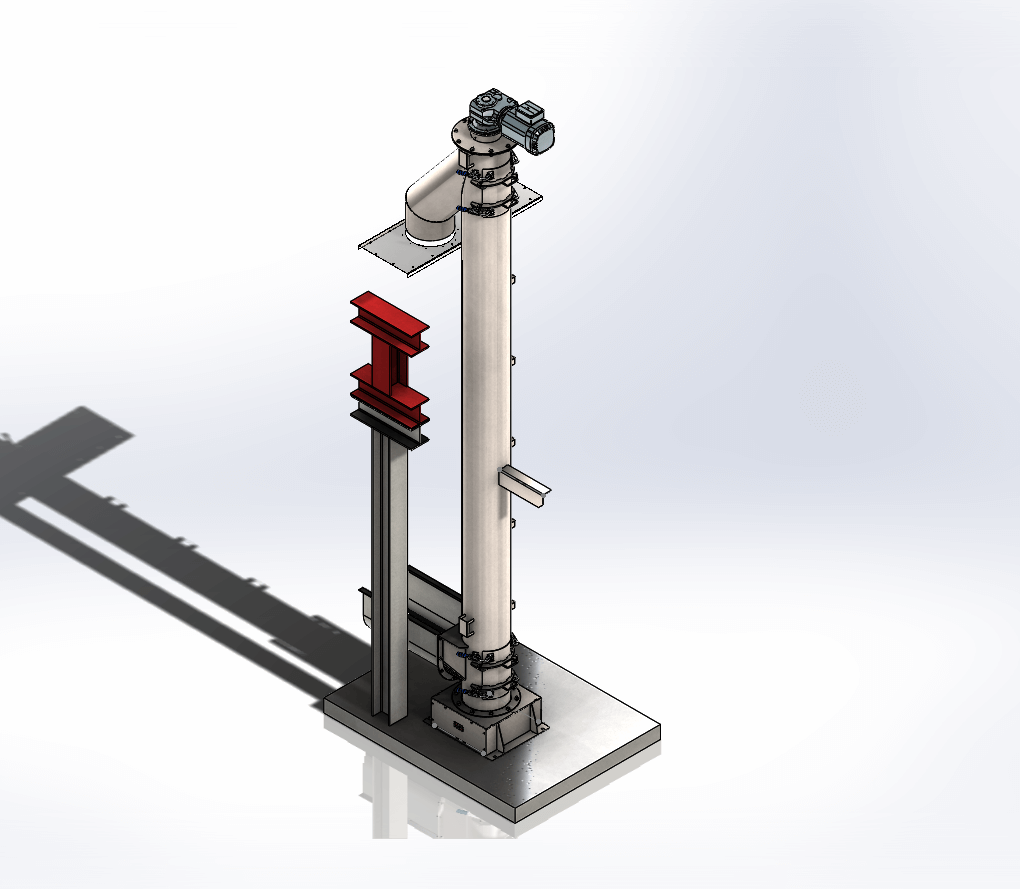

Vertical screw conveyors are a way to elevate bulk material with compact designs. They do this with a fully enclosed, screw-like rotating shaft that moves the product upwards consistently.

Advantages of Vertical Screw Conveyors

There are many advantages of using Vertical Screw Conveyors in bulk handling. Vertical Screw Conveyors are used in hundreds of industries and expand upon the benefits of other screw conveyors.

- Vertical screw conveyors provide compact designs, so they don’t take up a lot of floor space. The conveyor will fit into most plant layouts.

- Vertical screw conveyors have few moving parts and are cost-effective and easy to install and maintain.

- Vertical screw conveyors can come with additional features to make them easier to clean and maintain. For example, they can include covers that are quick to remove. They can also come with drop-bottom casings and even internal spray systems.

- Vertical Screw conveyors can be signed to heat or cool product by being jacketed or including a hollow-flight design.

- Vertical screw conveyors are flexible. They can move a wide variety of product, including grain, feed, waste, sludge, dirt, dust, and semi-liquid materials. They can also be installed at an incline or entirely vertical to suit a variety of applications.

- Screw conveyors can be used for mixing product as it is being conveyed. They can also be used as a de-lumper in some applications.

- Screw Conveyors are fully enclosed, ensuring that no product is spilt and wasted. This also makes sure no contamination affects your employees, keeping costs associated with illness down.

- Vertical Screw Conveyors can be used to meter product. It can take a product from a hopper or bin into the process stream at a specified rate, ensuring an automated, precise product portion.

- Our vertical screw conveyors can be designed without a centre pipe. This enables our conveyors to move large, irregular objects effectively.

The Right Vertical Screw Conveyor for your Business

Our Wrights Dowson Engineers use modelling techniques and 3D CAD software to design bespoke applications for any industry. With the correct specifications, we can create tailored vertical screw conveyor solutions to suit your industrial plant.

Simply provide us with information about your processes and space.

We’ll need to know about:

- The material that will be handled, including the particle size and density and its condition

- Whether the material will need heating or cooling

- The discharge rate you expect

- The height and girth of the vertical screw conveyor

- dditional specifications, like accessible cleaning applications

Learn More

The Wrights Dowson Group is a reliable and trusted manufacturer of vertical screw conveyors. Our bespoke designs meet your specifications to fit seamlessly into your operations. Aside from screw conveyors, we also design rotary shaft seals, bin activators and hoppers.

If you want to find out more about our vertical screw conveyors, get in touch with us today at the Wrights Dowson Group. We’ll be happy to provide you with advice, technical support and a quotation.